The process of preparing waste-recyclable glass for grinding

Collection: Waste parts of glass used in processing facilities are collected.

Sorting: The collected glasses can be of different colors and types. In the sorting stage, the glasses are separated by color and type. Any metals, plastics, or other foreign materials in the glasses are also separated during this stage.

Cleaning: The sorted glasses are cleaned and freed from foreign materials.

Sifting: Ground glass pieces are sifted through a sieve to separate unwanted residues.

Approximately 60 tons of prepared glass powders are pressed in eccentric presses in the desired dimensions. During this process, the coloring is also carried out.

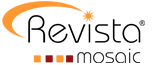

The printed glass mosaics are fired in closed-loop kilns approximately 22 meters long at a temperature of around 800 degrees.

After the baking process, the mosaics are placed in waiting containers.

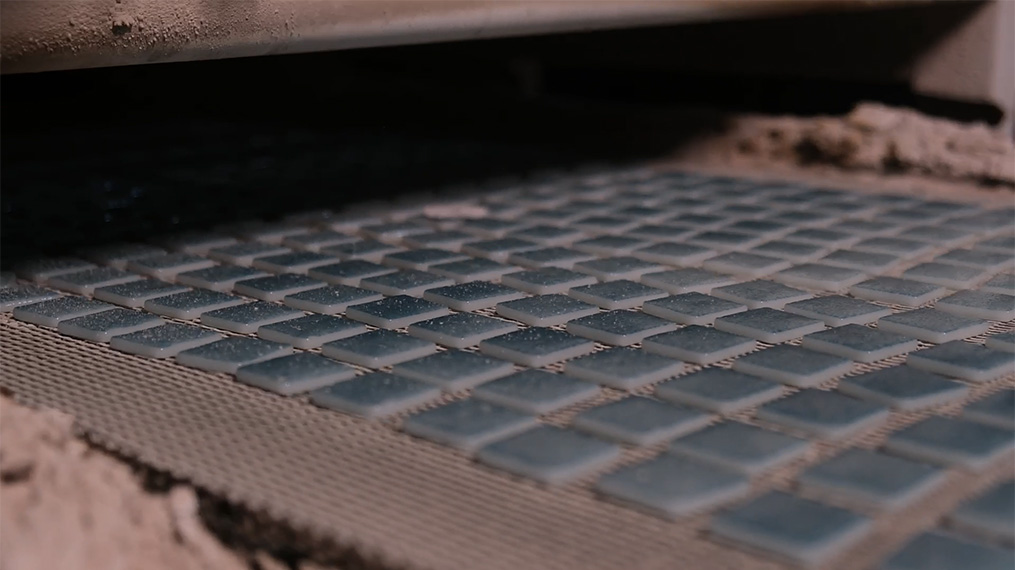

The stones that have been produced and gone through the cooling process are arranged in the desired patterns.

The finished glass mosaics are prepared for shipment through packaging and palletizing processes

Carefully crafted Revista and Revipool branded glass mosaics are shipped to more than 20 countries.